THE Highest Quality Floors at THE Lowest Price:

Congrats! You're one of the lucky ones to find THE BEST, most durable, 100% waterproof floors on the planet - SUPERCore®

SUPERCore® is a revolution in waterproof, rigid core plank flooring created exclusivly by WeShipFloors.com. Our resources led to the creation of an accessible, durable, and awesome product - SUPERCore®, the best waterproof flooring for your home or business at a great price.

Featured SUPERCore® products

-

SPC011X SUPERCore Xtreme Tennessee River Hickory 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sf/ctn) - Low Stock ETA 5.21

19 reviews4.84 / 5.0

(19) 19 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC006X SUPERCore Xtreme Solitude 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sf/ctn)

7 reviews5.0 / 5.0

(7) 7 total reviews

Regular price From $3.99Regular priceUnit price / per -

SPC039X SUPERCore Xtreme French Oak 6mm x 7" x 60" Waterproof Rigid SPC Plank - Low Stock, ETA APPX 4/28

8 reviews5.0 / 5.0

(8) 8 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC025X SUPERCore Xtreme Wild Acacia 6mm x 7" x 60" Waterproof Rigid SPC Plank 29.74 sf/ctn

11 reviews4.73 / 5.0

(11) 11 total reviews

Regular price From $3.99Regular priceUnit price / per -

SPC010X SUPERCore Xtreme Farmwood 6mm x 7" x 60" Waterproof Rigid SPC Plank 29.74 sf/ctn - On Backorder

13 reviews4.85 / 5.0

(13) 13 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC066X SUPERCore Xtreme Gunmetal Oak 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sf/ctn)

7 reviews5.0 / 5.0

(7) 7 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC021X SUPERCore Xtreme Oak Gunstock 6mm x 7" x 60" Waterproof Rigid SPC Plank 29.74 sf/ctn

7 reviews5.0 / 5.0

(7) 7 total reviews

Regular price From $3.99Regular priceUnit price / per -

SPC033X SUPERCore Xtreme Bay Breeze 6mm x 7" x 60" Waterproof Rigid SPC Plank 29.74 sf/ctn - Low Stock

2 reviews5.0 / 5.0

(2) 2 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC020X SUPERCore Xtreme Oak Natural 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sqft/ctn)

3 reviews5.0 / 5.0

(3) 3 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC009X SUPERCore Xtreme Barnwood 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sf/ctn)

9 reviews4.44 / 5.0

(9) 9 total reviews

Regular price From $3.99Regular priceUnit price / per -

SPC024X SUPERCore Xtreme Maple Brown Sugar 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sqft/ctn)

4 reviews4.75 / 5.0

(4) 4 total reviews

Regular price $118.66Regular priceUnit price / per -

SPC034X SUPERCore Xtreme Sandal 6mm x 7" x 60" Waterproof Rigid SPC Plank

1 review5.0 / 5.0

(1) 1 total reviews

Regular price $118.66Regular priceUnit price / per

Learn more about SUPERCore

-

We have FREE SUPERCore Samples

Click the "Get A Sample" button on any SUPERCore or wood floor product page and order a pack of free samples today!

We have FREE SUPERCore Samples

Click the "Get A Sample" button on any SUPERCore or wood floor product page and order a pack of free samples today!

-

SUPERCore Room Visualizer

See SUPERCore in your space before you buy, with our SUPERCore Room Visualizer tool.

SUPERCore Room Visualizer

See SUPERCore in your space before you buy, with our SUPERCore Room Visualizer tool.

-

World Famous SUPERCore Smash Video

The video that started it all... SUPERCore SPC vs. the competition - WPC

World Famous SUPERCore Smash Video

The video that started it all... SUPERCore SPC vs. the competition - WPC

-

What's Happening This Week at WeShipFloors

From discounted pricing to new products, and everything in between.

What's Happening This Week at WeShipFloors

From discounted pricing to new products, and everything in between.

SUPERCore® collage

SUPERCore XT 8mm waterproof plank flooring

Order FREE Samples by clicking the Get Sample button on each SUPERCore XT 8mm waterproof plank...

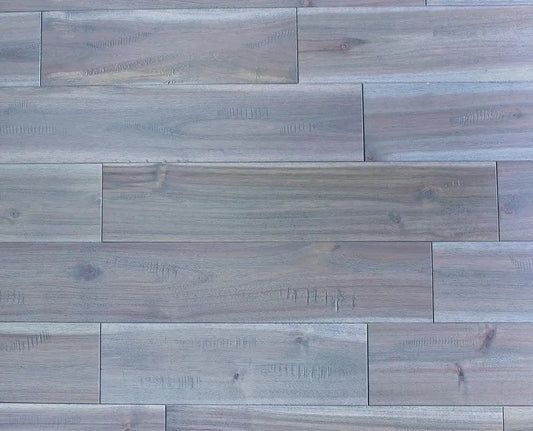

SPC064X SUPERCore Xtreme 30mil Sawtooth Gray 6mm x 7" x 60" Waterproof Rigid SPC Plank (29.74 sf/ctn)

SUPERCore Xtreme Tile - waterproof tile flooring

SUPERCore Xtreme Tile - waterproof tile flooring Create that stone look of...

What people are saying about our floors

-

SUPERCore® Xtreme

30 mil commercial wear layer

6mm thick w/ padded underlayment

5 foot planks, 12 x 24" Tiles

and 5" x 24" Herringbone

Lifetime Warranty

-

SUPERCore® Xtreme XLT

30 mil commercial wear layer

8mm thick w/ padded underlayment

5 & 6 foot long planks

Lifetime Warranty

-

SUPERCore® Basics

12 mil residential wear layer

4.5mm thick w/ padded underlayment

4 foot long planks

20 year Warranty

Engineered Hardwood

-

MSW23 Acacia Natural 1/2 x 5" Hand Scraped Small Leaf - Call 844-356-6711 for BEST price!

2 reviewsRegular price $0.01Regular priceUnit price / per -

AF021 Acacia Natural 9/16" HS Small Leaf Engineered - Call 844-356-6711 for BEST price!

1 reviewRegular price $0.01Regular priceUnit price / per -

AF164 Antique Hickory Bandit 1/2 x 7-1/2" Hand Scraped Engineered - Call 844-356-6711 for BEST price!

2 reviewsRegular price $0.01Regular priceUnit price / per -

AF162 Antique Hickory Kasper 1/2 x 7-1/2" Hand Scraped Engineered - Call 844-356-6711 for BEST price!

1 reviewRegular price $0.01Regular priceUnit price / per -

AF069 Elm Gunstock 9/16 x 5" Hand Scraped Engineered - Call 844-356-6711 for BEST price!

1 reviewRegular price $0.01Regular priceUnit price / per

Solid Hardwood

-

MSW30 Sawmill Hickory Natural 3/4 x 4-3/4" Wire Brushed Solid - Call 844-356-6711 for BEST price!

3 reviewsRegular price $0.01Regular priceUnit price / per -

MSW200 Acacia Natural 3/4 x 5" Hand Scraped Small Leaf Solid - Call 844-356-6711 for BEST price!

3 reviewsRegular price $0.01Regular priceUnit price / per -

MSW26 Australian Oak Calhoun 3/4 x 5" Hand Scraped Solid - Call 844-356-6711 for BEST price!

1 reviewRegular price $0.01Regular priceUnit price / per -

Brazilian Cherry Natural 3/4" Solid - Call 844-356-6711 for BEST price!

1 reviewRegular price $0.01Regular priceUnit price / per -

AF154 Asian Walnut Winterbean 3/4 x 5" Hand Scraped Solid - Call 844-356-6711 for BEST price!

Regular price $0.01Regular priceUnit price / per

-

Free SUPERCore Samples

Order 5 free SUPERCore flooring samples to see how our floors look in your home.

-

BEST Price Guarantee

To guarantee you get the BEST price, we'll work to beat any competitor's pricing.

-

Flooring Questions

Want to speak to us about your project? Text us below or call 844-356-6711